High Production Capacity Long Service Time Fully Automatic Door

Frame Roll Forming Machine

1. Description of Door Frame Roll Forming Machine

The door frame forming machine is a roll forming machine used in

the steel plate cold forming industry. It can continuously shape

the steel plate through an automatic press according to the

customer's requirements and cut flies to a certain length.

A door frame roll forming machine generally consists of a decoiler

(a Hydraulic Decoiler is optional), a main roll forming unit, a

transmission system, a cutting tool, a hydraulic system, a

hydraulic oil pump, a PLC control cabinet, and run-out tables

The punching also can be designed according to your needs. the door

frame surface will be very smooth and beautiful without any

scratches on the surface.

This Door Frame Roll Forming machine can produce various kinds of

Roll Formed Aluminum & GI Steel Door or Window frames.

2. Technical Parameters of Door Frame Roll Forming Machine

| Weight | About 6000kgs |

| Size | About 7.5m*1.2m*1.0m (L x W x H) |

| Suitable Material | Galvanized steel strip |

| Thickness | 0.8~1.2mm |

| Coil width | 240mm |

| Yield strength | 235Mpa |

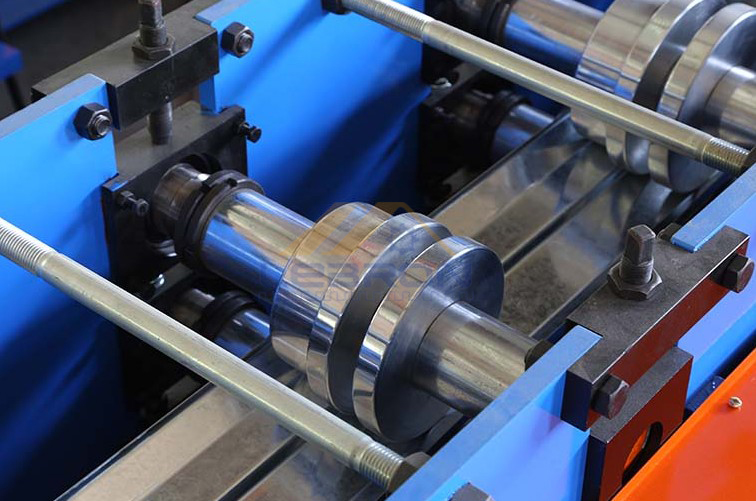

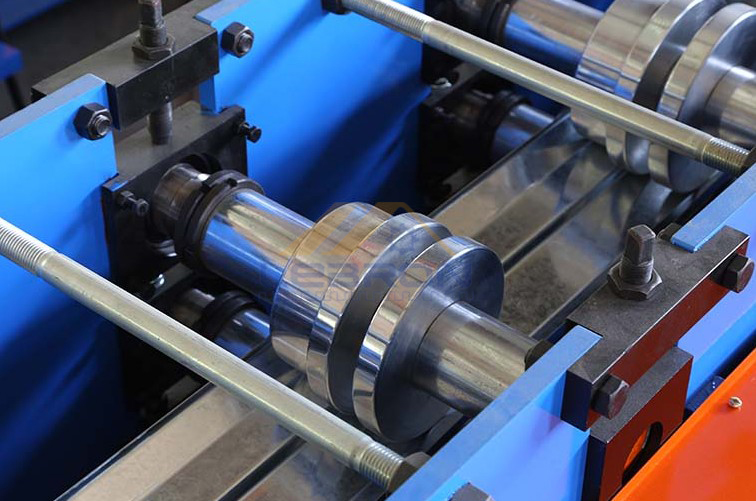

| Rollers station | 18 Stations |

| Roller Shaft Diameter | 75 mm |

| Roll Forming Speed | 20-25m/min |

| Production Speed | Approx.15m/min |

| Roller Material | 45# steel, coated with chrome, quenched |

| Cutter material | Cr12 mold steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric power requirement | Main power: 7.5 KW |

| Hydraulic power: 4 KW |

| Electric voltage | 380V 50Hz 3 Phase (as per local requirement) |

3. Main components of Door Frame Roll Forming Machine

| Name | Quantity |

| Uncoiler | 1set |

| Coil sheet guiding device | 1set |

| Main roll forming system | 1set |

| Punching device | 1set |

| Cutting device | 1set |

| Hydraulic station | 1set |

| PLC control system | 1set |

| Support table | 1set |

4. Our Service

After the machine arrives at the destination, the seller will send

the technician to the buyer’s factory to install the machine if the

buyer wants. The buyer needs to provide some technicians to assist

in the installation work.

The installation period is around 5 days. The buyer should have

been prepared for the steel sheet, and foundation position of the

machine before the seller’s technician's departure.

The buyer should arrange the accommodation, food, and traffic in

the destination

Training period: 2 days. (we can supply training on the operation

spot if the buyer needs)

Within 3 months after the arrival of the goods at the port of

destination, if there is no installment requirement from the

Buyers, the goods should be counted as up to standard. The

inspection standard is based on the technical standard signed by

both parties and our company standard.

5. FAQ

1Q: Are you a factory or trading company?

1A: We are a factory.

2Q: Where is your factory located?

2A: Our factory is located in Wuxi City, Jiangsu Province, China.

You are warmly welcome to visit us!

3Q: What should I provide if I would love to customize the machine?

3A: We need profile drawing, and material information, such as

feeding width, thickness, yield strength of steel coil, voltage and

your special requirements.

4Q: What I should do if I just start to know roll forming

machinery?

4A: Contact us immediately, we provide free consultant pre-sales

service.

5Q: Can you make the machine according to my design or phototype?

5A: Yes. We have a professional designer for working out the most

suitable design and production plan for the machine that you are

going to book with us

6Q: How can I trust you that machines passed testing running before

shipping?

6A: We record the testing video for your reference. You are welcome

to visit us and test the machine in our factory.

7Q: Do you provide installing and training overseas?

7A: Overseas machine installation and worker training services are

optional.

8Q: How is your after-sales support?

8A: We provide technical support online as well as overseas

services by skillful technicians.

9Q: Guarantee period:

9A: Within one year from the date of finishing commissioning. The

guarantee covers all the electric, mechanic and hydraulic parts in

the line except for the easy-worn parts.