10-16m/Min Speed Corrugated Roof Sheet Roll Forming Machine

Hydraulic Cut PLC Control

1. Product Description

1. the advantage of corrugated steel making machine

it has reasinable structure, beautiful appearance, with advantage

of saving space, easy operate and especially welcomed by the

costomer with limit area or site operation.

2. Main Parameter and specification of corrugated steel making

machine

We design each machine according to user requirement.

Below techinical parameters can be adjusted if needed.

| roll forming machine |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1000mm |

| 3 | Thickness of the plate | 0.3-0.8mm |

| 4 | De-coiler | Manual one, can load 5 tons raw material |

| 5 | Rollers for forming | 14 rows |

| 6 | Diameter of the roller | 80mm |

| 7 | Rolling material | Carbon Steel 45# |

| 8 | Main motor power | 4kw |

| 9 | Productivity | 8-12m/min |

| 10 | Cutting method | Hydraulic mould cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kw |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 14mm |

| 16 | Main structure of the machine | 300 H steel |

| 17 | Weight | About 4.6T |

| 18 | Dimensions | 7.5*1.6*1.2m |

| 19 | Voltage | 380V 50Hz 3phases(changeable as needs) |

| 20 | Certificate | CE/ISO |

.

2. FAQ

Why Choose Us?

1) Q: Do you have after sales support?

A: Yes, we are happy to supply it.

2)Q: How do your machines compare with other big companies in this

market?

A: We are up to date with the latest technology and improve our

machines accordingly

3) Q: Will you deliver the right goods as ordered? How can I trust

you?

A: Yes, we will. The core of our company culture is honesty and

credit

Qinyuan is ALIBAB’s Gold supplier with BV assessment and CE

certificate.

4)Q:What can you do if the machine broken?

A:Our machine's warranty period is 18months,if the broken parts

can't repair

we can send the new parts replace the broken parts free,but you

need pay the express cost yourself if after warranty period

we can through negotiation for to solve the problems,and we supply

the technical support for the whole life of the equipment.

5) Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address we have rich

experience in transport.

6) Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,galvalume steel

coil,color steel coil,and aluminum coil.

3. Main components of corrugated roof roll forming machine

| Item | Model/name | Qty. | Technical details |

1.Decoiling system |

Hydraulic decoiler |

1 set | Capacity: Max. 5Ton,hydraulic control steel coil inner bore

expanding, shrinkage and stop. |

2.Forming machine | Material Guiding System | 1 set | For feeding in a right position no Deviation. |

| Precutting Device | 1 set | Prevent the profile being unbeautiful because of the rough

material. |

| Main Roll Forming Machine | 1 set | About 22 steps, motor driving and chain transmission. Wall plate

structure. |

| 3.Cutting system | Hydraulic Cutting Device | | Precutting and postcutting both. |

| 4.Hydraulic system | Hydraulic Station | 1 set | Providing the power of cutting. |

5.Control system |

PLC Control System |

1 set | PLC control system, encoder positioning and cut-to-length

automatically, touch screen operating. |

| 6.Racking system | Exit rack | 3 PC | no power. |

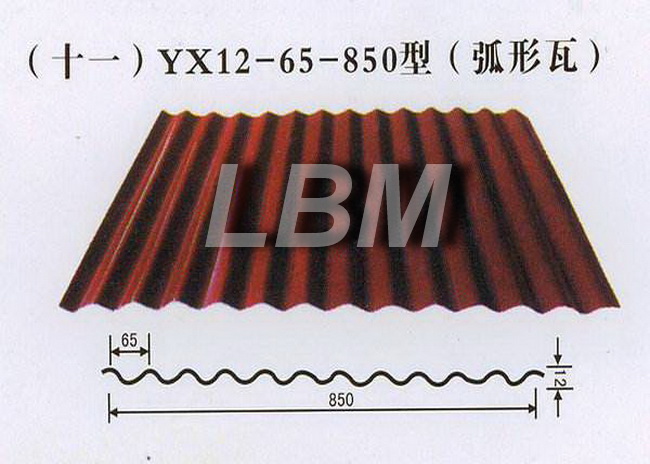

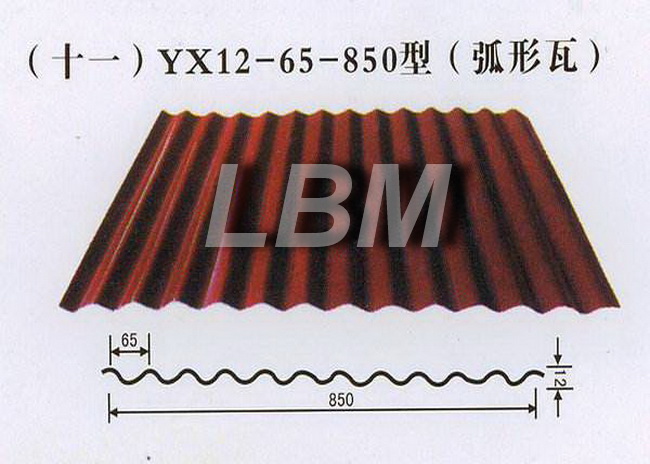

4. Roof sheet sketch

5. Our Service

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 22 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 3 years maintenance and whole life technical support

6. Picture