New type Double Layer Roll Forming Machine made in China PLC

Control Automatic

1. Double layer roof sheet roll forming machine description

The double-layer roof sheets are rolled and molded, which are both

solemn and elegant, and are beautiful. The appearance is smooth,

ripple is uniform, the utilization rate is high, the strength is

high, the production automation is high, the cost is low and

durable.

Double-layer roof sheet roll forming machine products are widely

used in large and medium-sized enterprises of civil construction,

such as plant, garage, hangar, stadium exhibition hall, theaters

and so on.

2. Main technical details of double layer roof roll forming machine

| Item | Technical parameter |

Suitable Material | Type | PPGI/GI/PPGL |

| Thickness | 0.3-0.8mm |

| Wide | 914mm/1000mm/1200mm/1250mm/1450mm |

| Yield Strength | 230~550MPA |

Product

Specs | Profile | Customized profile |

| Effective width | Base on customized profile |

| Length | Any length |

Power

Specs | Voltage | 380V/3PH/50HZ, accept customization |

| Main Motor | 5.5kw |

| Hydraulic motor | 4kw |

| Hydraulic pressure | 10-12MPa |

Machine

Specs | Forming steps number | 13~20 steps |

| Shaft Material | 45 # steel tempered, 70~90mm |

| Roller Material | 45 # steel chrome coated |

| Main machine body | 350# H steel welded |

| Transmission | Chain and Sprocket, chain size 1.5 inch |

| Wall Plate | 16mm thickness |

| Blade material | Cr12 mould steel with quenched treatment 60-62 |

| Forming Speed | 8-12m/min for standard solution |

| Cutting system | Length-set cutting after roll formed

and could pre-cutting to switch off the coils |

| Control System | Delta PLC and Converter |

| Manual decoiler | Max width of coiling: 1000~1450mm

Max weight of loading: 5000kg |

| Output Supporter | 2 Pcs Simple Supporter |

| Dimension of the machine | 7.5m~11m1.5mm1.2m |

| Weight of the machine | 3.5 ton ~6 ton |

3. Introduction of main components of double layer roll forming

machine

1). Manual Decoiler: 2 sets

Un-powered,Manually control steel coil inner bore shrinkage and

stop,

Coil inner diameter is 500-- 508mm

Capacity: Max. 5 Ton

2). Main machine:

With feeding material guide, body frame made from H350 type steel

by welding;

Rollers manufactured from 45# steel,CNC lathes,Heat Treatment, hard

Chrome Coated;

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving, about 18/16 step to form

Main Motor=5.5KW , Frequency speed control

Forming speed approx.13-15m/min

3). Hydraulic Cutting device:

Cutter frame made from high quality 20mm steel plate by welding

Post cut, stop to cutting,Two pieces cutting blades,no blanking

Hydraulic motor: 2.2KW Cutting pressure: 0-8Mpa

Cutting tool material: Cr12, Heat treatment

4). PLC Control System:

Touch screen brand:Taiwan WEINVIE ,PLC and Converter brand: Taiwan

DELTA,Encoder brand:Japan Koyo

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

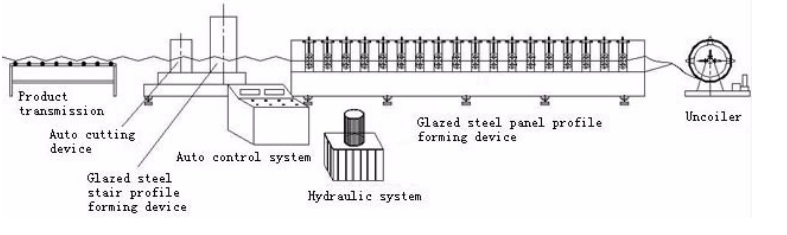

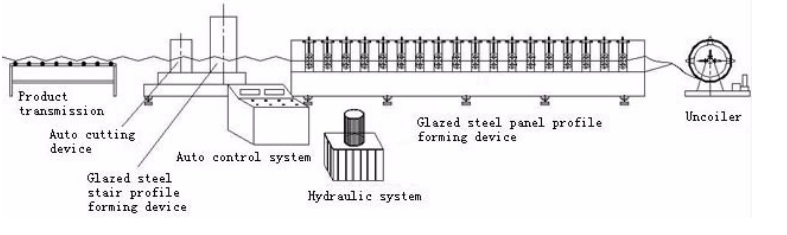

3. Double layer roll forming machine flow chart

4. Quality assurance

The company organizes the production as per ISO9001:2008 standard.

From design control, process control, inspection control to

delivery, installed and service, we all operating a whole strict

process control system. The running of the quality system performs

quality manual, procedure files, work instruction and related

technical and management standard together with standard and

regulation layout by the company. Quality system realizes whole

screw and whole procedure control completely.

Quality assurance procedure for important out-source parts.

a. Mainly out-sourced parts: control system, cylinder, hydraulic

components, motor, pump etc.

b. After evaluation, select qualified suppliers as business

partners.

c. Purchasing according to plan, purchase contract, quality

requirement, technical standard, and inspection standard.